Zinnwald Lithium Project is located in the village of Zinnwald (Altenberg, Sachsen), Germany and is owned by Zinnwald Lithium plc.

SRK provided ad hoc technical services to Zinnwald Lithium from 2022 to May 2024. This included conceptual geotechnical and mining method trade off studies for different cut-off grades, production rates and sequences.

From November 2023 to May 2024, SRK further provided mine planning support, covering :

- Mining assumptions and options: mining method, mining sequence, backfill approach, access options to the underground mine and underground crusher location;

- Stope optimisation update;

- Material handling systems trade-offs;

- High-level mine design; and

- High-level schedule for the first 3 years.

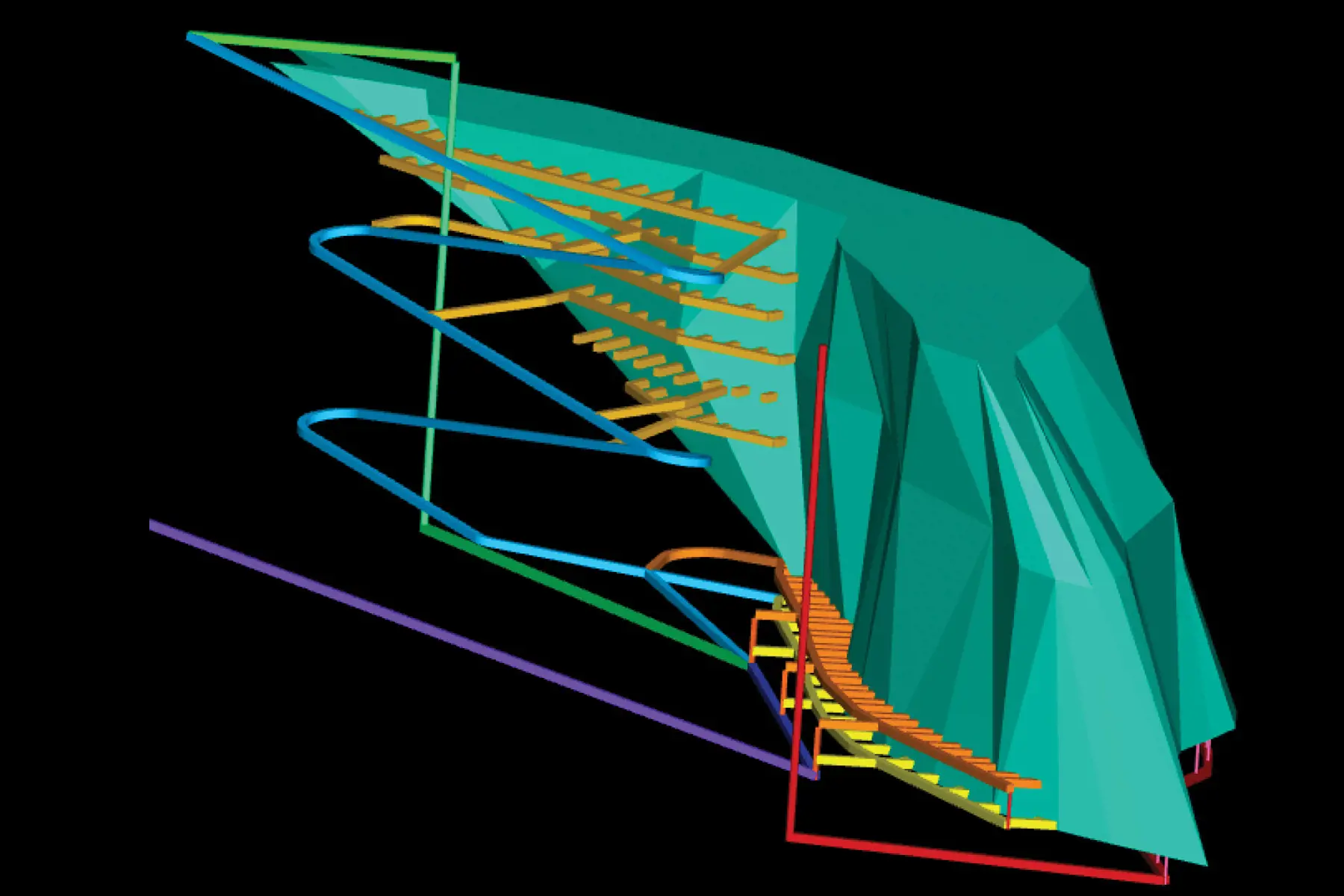

The primary crusher and backfill plant were located underground, to minimise the project’s surface footprint. The preferred mining method was longhole open stoping, with a bottom-up sequence, with backfilling (further backfill studies to be completed).

SRK further studies the material handling system options, split into two categories:

Production levels to the crusher (two options were assessed):

A. Loaders operating in production levels dump directly into ore passes. Material is then hauled by trucks along the infrastructure level to the crusher.

B.Trucks operating in production levels dump directly into ore passes to the crusher.

Crusher to the processing plant: Crushed material is conveyed 10 km underground to the processing plant on surface.

Relevant production levels and infrastructure were designed to identify the development required with the data available at the moment. These levels were used to assess development requirements and mineral inventory for the overall mine plan. Further analysis incorporated mine design criteria and modifying factors to develop a conceptual mine plan and the schedule for the first three years of production within the Life of the Mine.