Transmissivity (T) and hydraulic conductivity (K) values can be determined cheaply, instantly, and reliably from new monitoring bores using the inevitable airlift development that occurs during their construction.

The methodology requires only the measurement of discharge (Q) using a bucket or V-notch weir, and the residual drawdown (Δsr), recorded with a level logger once the compressor is turned off. Calculations are based on the Theis (1935) equation. Neither the maximum drawdown nor the static water level (SWL) is required.

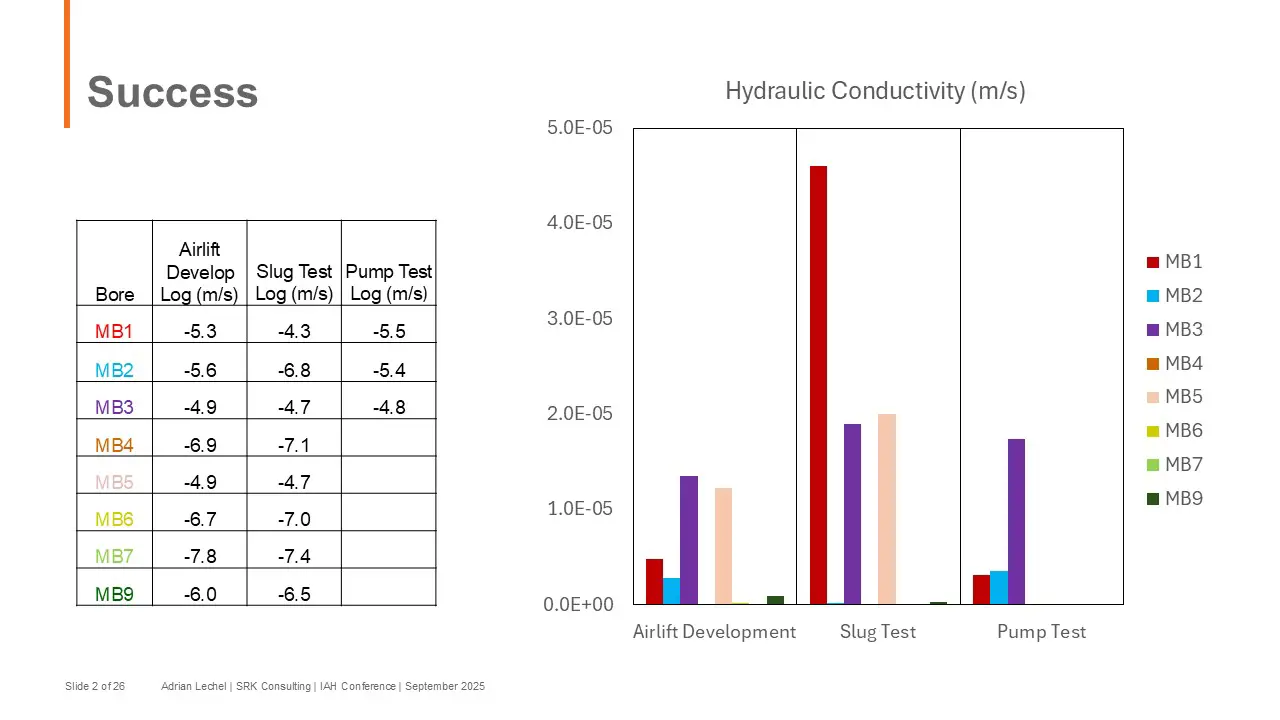

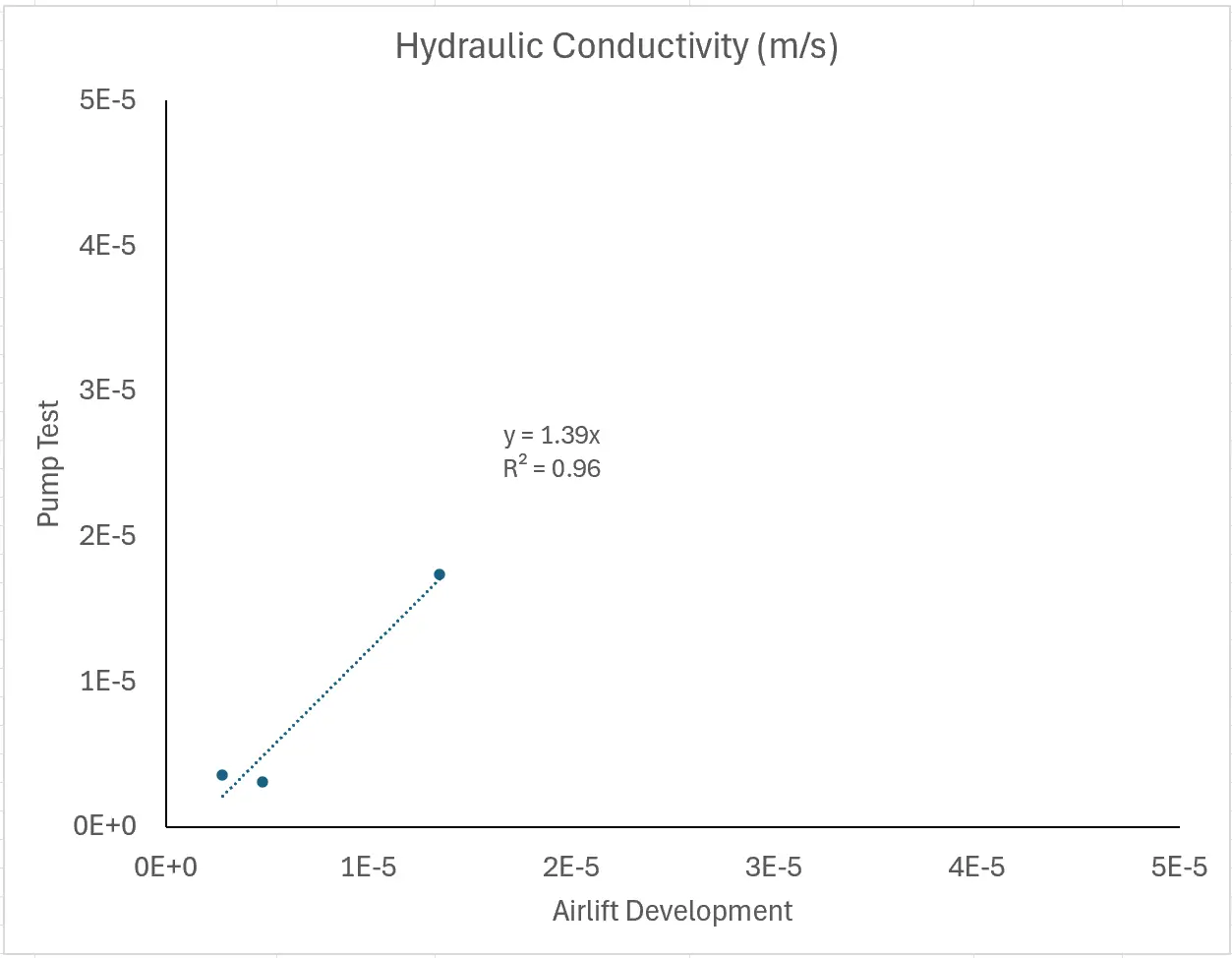

Benchmarking T and K values obtained from airlift development in three monitoring bores against subsequent pumping tests conducted at the same locations demonstrated excellent accuracy—differences appeared only at the decimal level. Furthermore, results from the airlift method outperformed falling head tests (also known as slug tests), which were also conducted at the same bores.

Two to four hours of airlift development, followed by inserting the level logger within 15 minutes after switching off the compressor (typically operated for about 20 minutes), was sufficient to measure Δsr.

This methodology is particularly valuable for determining T in low-yielding monitoring bores where conventional pumping tests are not feasible. It provides unbiased hydraulic data for every new monitoring bore, substantially enhancing the assessment of spatial heterogeneity of the penetrated formation.

The approach incurs no additional costs to the drilling campaign. Its results are immediately available, enabling real-time adjustments to drilling operations.

Longer level logger recordings—spanning several hours to days until SWL recovery—can reveal diagnostic curves potentially influenced by boundary conditions.

This approach might also be adaptable to air-core (AC), reverse circulation (RC), and rotary air blast (RAB) holes during resource drilling campaigns, offering a method to estimate T from every mineral exploration hole.

Additional pumping test data is required to draw statistically significant conclusions, as the current case study includes only three monitoring bores (n = 3).