Despite a number of short-falls, the IPI SWIPS Double Packer provides accurate results with budgetary savings.

Unlike the standard (single) packer system, the double IPI SWIPS has two packer elements which means that the tested interval is located between two inflatable isolating elements rather than between a packer element and the drillhole bottom, as in a single packer system.

Furthermore , the double packer is installed inside a standard drill tool, such as a Boart Longyear, instead of in the core barrel and partially extends into an open borehole section (below the crown) by a few metres Special expanders inside the drill string between the landing ring and the crown provide the necessary stabilisation.

A double packer allows tectonic faults and large fractures of small thickness (from 1.5 to 8 m) to be tested separately, which is important for gathering hydrogeological information as groundwater inflow to the mine workings is often controlled by water conductivity of tectonic faults, various geological structures and fracture systems.

A double packer has advantages for obtaining hydrogeological data because testing can be carried out after borehole drilling is finished, without the need for repeated interruptions of drilling process for testing. When borehole drilling is completed and information is available on intersected structures and lithologies, the packer installation intervals can be more accurately defined .

Double packers help to make significant budget savings provided that the drilling speed is low (less than 40 m/day) and boreholes are deep (over 500 m), and because presence of a hydrogeologist at the deposit during the drilling process is not required. In addition, the idle time of a drilling rig is cut.

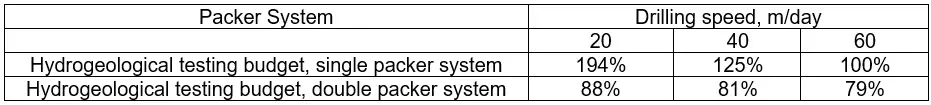

The relative costs of use of different packer systems depending on the drilling speed (at drilling lengths over 5000 m) are estimated in the table:

Whilst there are advantages in using a double packer, there are also some short-falls:

- The thickness of tested interval usually does not exceed 5-7 m; numerous expensive spare parts are needed for thicker intervals, and the assembling/dismantling processes is much more difficult.

- Due to more complex design, the double packer assembling/dismantling takes 10-20% longer compared to single packer.

- Double packers are 20-30% more expensive than a conventional single packer. Similarly, wear of packer elements is twice as high due twice as many elements.

- It is hard to control the tightness of tested interval shut-off and if one of the elements deflates, it is hard to determine which one.

- Double packer is often used for testing filtration parameters of faults, with the lower packer element installed only 1-2 m below the fault. Since the fault zone is often unstable, rock falls are highly likely during pumping out process and the lower packer element may be damaged by these rock falls during dismantling.

Conclusions

Double packer systems are more complex and expensive, and experienced specialists are needed to operate efficiently; however, more accurate results can be obtained when determining hydrogeological parameters and costs can be reduced when drilling at a low speed.

SRK has an extensive experience of successful hydrogeological tests with the use of double packer system at depths up to 1000 m (HQ).