Dedicated geotechnical drilling for exploration projects generally form a small percentage of the overall drilling conducted for exploration, resource definition, and metallurgical testing. Within this broader dataset of exploration data, site geologists log basic geotechnical parameters including Rock Quality Designation (RQD) and Total Core Recovery (TCR).

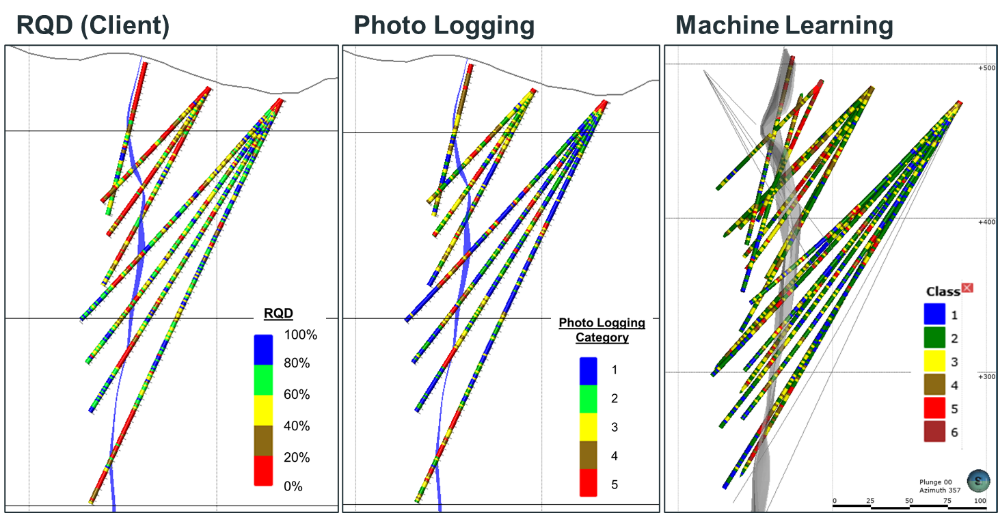

There can be challenges with improper collection of these basic geotechnical data and limitations to their usefulness within certain geological contexts. Reliability of the mine design is contingent on being able to extrapolate these limited geotechnical drillholes and available basic geotechnical logging from resource drilling for delineation of geotechnical domains. Uncertainties within the RQD data of the resource dataset can limit the effectiveness and validity of this methodology, generally leading to cost- and time-intensive core photo reviews to verify geotechnical domains.

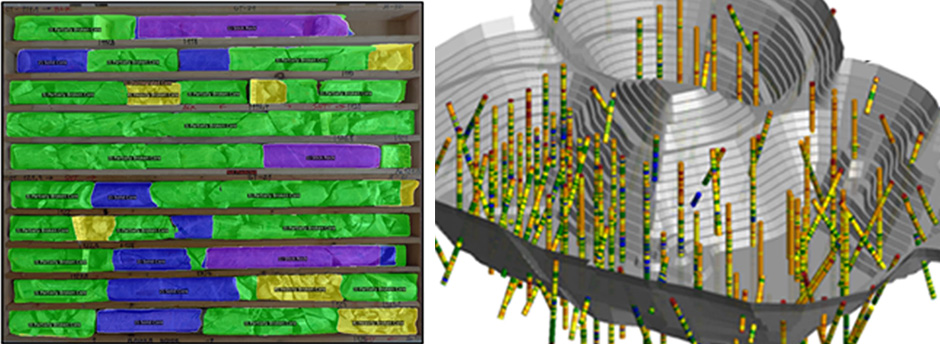

Machine Learning (ML) workflow involving the use of computer vision and deep neural networks was developed by SRK for use in the geotechnical classification of diamond core box photographs. The methodology involves an assessment of the degree of brokenness of the drill core in the core boxes. For each project, algorithms are trained using a representative selection of core box photographs labelled with a qualitative classification system. The trained algorithm identifies and maps similar conditions to these defined categories in available core box photographs for the entire project. The classification categories can be refined on a project basis to adapt to deposit type and associated range of rock mass conditions. The quality of the results is checked by SRK to determine the level of accuracy and resolution of the data collected.

Explicitly, this workflow provides a detailed dataset that can be used to inform components of the geotechnical domain model. This workflow still relies on experience-based interpretation of the causes of the degree of brokenness in the core boxes, which could be attributed to many factors including lithology, alteration, micro-defecting, weathering, and structures.

SRK has validated the workflows against exploration recovery data (i.e., RQD, TCR) and manual photologging. The results of the ML workflow demonstrate a consistently classified outcome (Figure 02). Capable of resolving intervals of less than 10 cm, the ML output is far more detailed than what can be practically achieved through manual photologging. This approach to automated characterization of core images provides the ability to efficiently collect a very large geotechnical dataset at early project stages to inform technical studies and reduce uncertainty in the design. Initial project experience suggests that ML can be implemented for less than 10% of the time and costs associated with manual photo reviews.

Andrew LeRiche

Consultant Rock Mechanics Engineer

Andrew specializes in geotechnical characterization and domaining for mining projects.