Starting Q3 of 2023, SRK Canada will offer XRT sensor-based testing in partnership with Base Metallurgical Labs, located in Kamloops, BC.

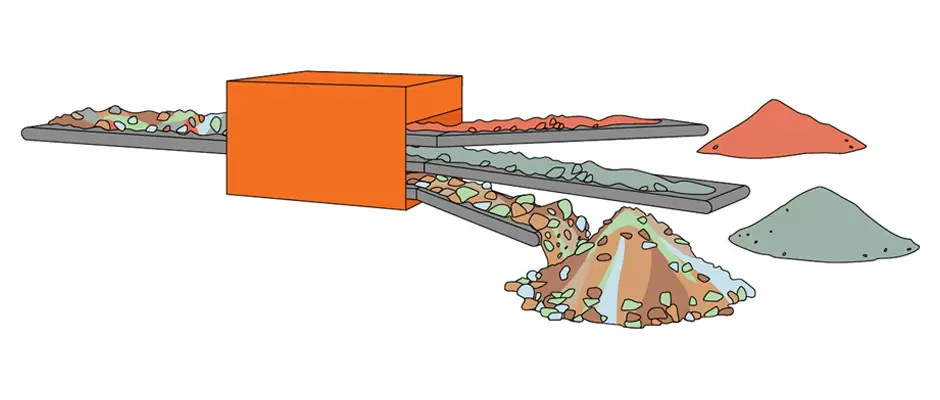

Used in conjunction with crushing/screening, our XRT sensor testing rapidly—and cost effectively—assesses the potential for pre‑concentration, which can then be applied to scoping or prefeasibility studies.

Our unique testing method estimates how much material will bypass a sorting unit as fines along with the associated metal upgrades. It can characterize deposits (or low-grade stockpiles) using small drillcore samples—even half-core samples—cutting down sample mass requirements. Using a lab-scale XRT unit, a tray of coarse particles can be scanned in a few seconds and results can be provided within 24 hours.

SRK and Base Metallurgical test and analyze sample results using a standardized procedure, which allows for benchmarking against other projects and operations. The goal is to enhance interpretation of scan results over time using machine learning.

Our XRT sensor testing can be included in metallurgical testing programs with minimal sample loss and no disruption. It can also be supported by larger-scale performance testing already being done by sorting equipment manufacturers.

For more information, contact Adrian Dance, Bob McCarthy, or Hamid Hatami.

Click here to watch the presentation "Pre-Concentration Methodology: Lab-Scale Evaluation Test".

See our interactive infographic.